|

|

Paramount ME Web Site |

|

|

Paramount ME Web Site |

Figure 1: A 31 cm (12-inch) Software Bisque Paramount ME/MX Permanent Pier

The Software Bisque Paramount ME/MX Permanent Pier (sold separately) is available in heights ranging from 30.5 cm to 122 cm (12-in to 48-in). Software Bisque generally stocks 30.5 cm (12-in), 46 cm (18-in) 61 cm (24-in.), 91 cm (36-in.) and 122 cm (48-in.) piers. Custom height piers require 10-12 weeks delivery.

Please call for availability!

|

Pier Height cm (in) |

Pier Weight kg (lbs) |

Typical Availability |

|

31 (12) |

19 (42) |

Immediate |

|

46 (18) |

22 (48) |

Immediate |

|

61 (24) |

25 (54) |

Immediate |

|

76 (30) |

26 (58) |

Immediate |

|

91 (36) |

29 (64) |

Immediate |

|

122 (48) |

35 (76) |

Immediate |

|

*Custom Height |

26 (58) + 2.7 kg (6 lbs.) per 2.5 cm (1-in) over 76 cm (30-in.) |

10-12 weeks |

The bottom of the Paramount ME/MX Permanent Pier has four slotted holes that provide approximately 10 degrees of rotation (± 5 degrees) for polar azimuth adjustment. The Paramount ME/MX Permanent Pier is constructed of two steel plates welded to a 25.4 cm (10-in.) diameter steel tube. Piers are powder coated on both the outside and inside to protect the steel from corrosion.

Figure 3: Photograph of Paramount ME/MX Permanent Pier base plate. Note the slotted holes for polar azimuth adjustment.

Pier Base Plate

Pier base plate dimensions shows the footprint of the Paramount ME pier. The pier can be attached to the ground with four 12.7 mm (0.50-inch) J-bolts placed in the concrete (J-bolts are available from any hardware store). We recommend that the base plate remain in contact with the cement surface to optimize damping.

Figure 4: Software Bisque Paramount ME/MX Permanent Pier Base Plate dimensions.

|

|

|

|

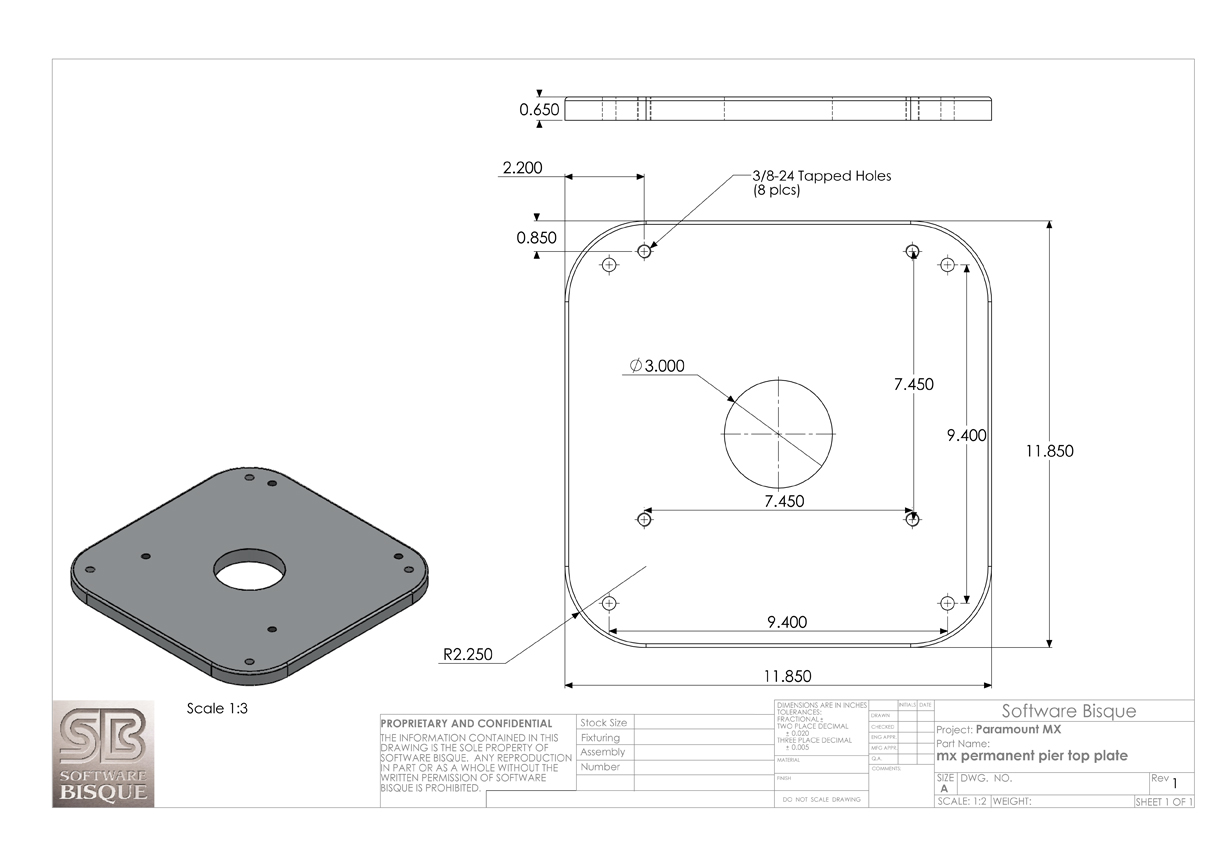

Figure 5: The Software Bisque Permanent Pier Top Plate |

Figure 6: Paramount MX mounted on a Paramount ME/MX Permanent Pier |

The top plate is constructed of 12.7 mm (0.50-inch) thick steel plate and is drilled to accept either the Paramount ME or the Paramount MX. The Paramount ME mounting holes are labeled 1-4 in yellow text in Figure 5. The Paramount MX mounting holes are labeled 5-8 in red text in Figure 5.

The direction to the Celestial Pole for the Paramount MX mounting option is indicated in the above drawing. The Paramount ME's 23.9 cm (9.40-inch) hole pattern is symmetric about the center of the pier, so the pier can be mounted at any multiple of 90-degrees for Paramount ME only installations.

The Software Bisque Permanent Pier Top Plate is slightly larger than the Base Plate to accommodate the Paramount ME base.

Figure 7: The Software Bisque Paramount ME/MX Permanent Pier Top Plate (PDF Version of the above graphic)

|

ME/MX Permanent Pier Component |

Thickness cm (in) |

|

Top plate |

1.27 (0.5) |

|

Bottom plate |

1.27 (0.5) |

|

Column |

0.32 (0.13) |

A common "litmus test" that astronomers use to "measure" an imaging system's overall stability is to gently tap the side of the mount and then watch a star's motion through the telescope's eyepiece. The behavior of the star can give insight to the overall stability of the pier, mount and telescope system.

For example, if after only a few oscillations, the star returns to its original position within about one second (or so), then the whole system is deemed "stable" and ready for imaging.

If, however, the star continues to oscillate for more that a few seconds, then one or more system components is either loose or somehow unstable. This can lead to problems when imaging and the mount is "moved" by wind or other sources of vibration (trains, highway traffic, etc.).

If you've stabilized every component of your imaging system (pier to mount, mount to telescope, eyepiece to telescope, filled the pier with sand), and still observe oscillations in the system, then check the pier to ground interface.

Problem

The interface between the pier's mounting surface (normally a concrete pier or pad) and the base plate of the Software Bisque Permanent pier can be a source for high-frequency oscillations.

This comes from the fact that the base plate is essentially "suspended" at the four corners, and may not be properly "grounded". The result is a mechanical "diaphragm" at the bottom of pier.

Since the pier is supporting a large amount of weight, small "taps" on the mount create a significant torque (force at a distance). So, a "weak link" is the pier's 0.5-inch thick metal base plate, which actually "bends" (by a very small amount) when the mount is tapped, and causes oscillations.

Solution

Place material to dampen vibrations between the pier's cylindrical bottom and the pier's mounting surface. Treated plywood is perhaps the best choice, and will last a very long time under most operating conditions.

Many Paramount ME customers report significant reductions in damping time using this technique.